Vise Sub Table

Vise Sub Table

Vise Sub Table

I first heard about the concept of a Vise Sub Table from The Tool And Die Guy. He presented the case for making one for his Kurt vise. The main points he makes are that it offers up more possibilities for work-holding than just a plain vise, and you can use it without having to remove your vise. The dowel pins also offer some great options for repeatable location of parts. It was pretty clear if I made one, it would get a lot of use.

Tom Lipton has described a similar sort of thing on his excellent Youtube channel. I think his is a bit smaller, and I believe he calls it a Mini Pallet. His is also more versatile, in that it can be transferred between mill vise and lathe chuck.

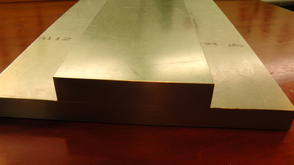

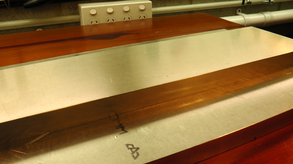

I made mine with a large table size, from aluminum, primarily to accommodate the large flat parts that I deal with, that need precise hole locations, like clock plates, bridges, wheels etc

Tom Lipton has described a similar sort of thing on his excellent Youtube channel. I think his is a bit smaller, and I believe he calls it a Mini Pallet. His is also more versatile, in that it can be transferred between mill vise and lathe chuck.

I made mine with a large table size, from aluminum, primarily to accommodate the large flat parts that I deal with, that need precise hole locations, like clock plates, bridges, wheels etc

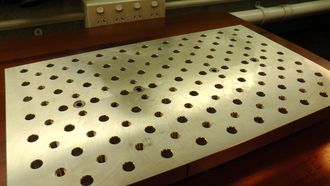

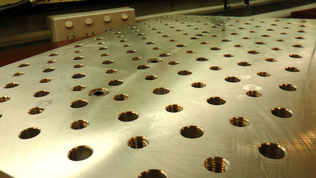

The table is tapped with an array of M8 holes and M10 dowel pin holes

The table is tapped with an array of M8 holes and M10 dowel pin holes

I chose to make it out of aluminum primarily because of the shortage of good steel in my area, but to be honest it works fine. I stiffened up the design a bit using a thick section down the middle, and it doesn't flex at all under the light loads I put on it. The hole array was tapped/reamed on the mill using the DRO.

I also made a purpose built clamping kit to use on it, as pictured below right.

It is a real pleasure to use this table. The vise jaws grip the thick section on the underside, and it sits like a rock. Virtually any shape of part can be held on it, and the part is accessible to the cutting tool from above and all sides, depending on what sort of clamping option is used.

I also made a purpose built clamping kit to use on it, as pictured below right.

It is a real pleasure to use this table. The vise jaws grip the thick section on the underside, and it sits like a rock. Virtually any shape of part can be held on it, and the part is accessible to the cutting tool from above and all sides, depending on what sort of clamping option is used.