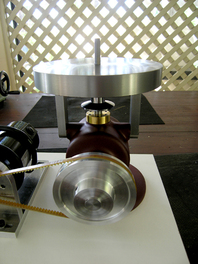

Die Filer or Bench Filing machine

A die filer is one of those tools that you see pop up from time to time in magazines or construction manuals. The owners of these machines always speak very highly of them, yet commercial manufacture of these tools ceased a long time ago. I had been looking for one on Ebay for years, and had even considered fabricating one from scratch, before finding this option available as a kit from Andy Lofquist at Metal Lathe Accessories.

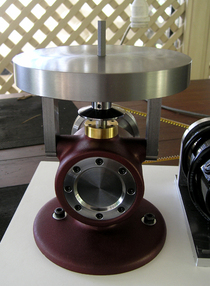

It is probably better described as "shop finished", rather than "shop made", mainly because most of the hard work has been done by Andy when he designed and made the castings. They really are top notch.

Having said that, there is a fair amount of machining required to turn the castings and other bits and pieces into a working tool. I learned a great deal from building it, and it gave me a lot of confidence to tackle some more complex projects. Of course I also ended up with a seriously useful tool at the end of the process.

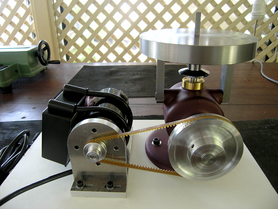

I use a Sherline motor and speed control to power it. The ability to slow the stroke speed to a crawl is essential to control the quality of the cut. Also, despite the fact that it is well balanced, any machine will build up a harmonic vibration at some speed in its range, so variable speed control is essential to shift away to a non-sympathetic rpm.

It wasn't cheap, especially with freight to Australia, but it was well worth the expense. It's a great tool to have, particularly for clockmaking, where there is just so much filing required to get a part completed. This tool takes care of the inside of corners, and due to the vertical action the surfaces remain nice and square to the part. Used in tandem with a 1" belt sander, the time to bring a part to the line is significantly reduced.

Andy has written great instructions for the construction process, and even though it was the most complex thing I had made at the time, I had few troubles completing it using my SX3 mill and 9x lathe. I did take it slow though... I was paranoid about ruining a casting, so I checked every set-up a dozen times before making cuts!

Andy also gives clear instructions on how to make the parallel machine files, from common hand files. Parallel machine files of the correct size and cut are not available in my area, and hard to find worldwide, so this is important.

It is probably better described as "shop finished", rather than "shop made", mainly because most of the hard work has been done by Andy when he designed and made the castings. They really are top notch.

Having said that, there is a fair amount of machining required to turn the castings and other bits and pieces into a working tool. I learned a great deal from building it, and it gave me a lot of confidence to tackle some more complex projects. Of course I also ended up with a seriously useful tool at the end of the process.

I use a Sherline motor and speed control to power it. The ability to slow the stroke speed to a crawl is essential to control the quality of the cut. Also, despite the fact that it is well balanced, any machine will build up a harmonic vibration at some speed in its range, so variable speed control is essential to shift away to a non-sympathetic rpm.

It wasn't cheap, especially with freight to Australia, but it was well worth the expense. It's a great tool to have, particularly for clockmaking, where there is just so much filing required to get a part completed. This tool takes care of the inside of corners, and due to the vertical action the surfaces remain nice and square to the part. Used in tandem with a 1" belt sander, the time to bring a part to the line is significantly reduced.

Andy has written great instructions for the construction process, and even though it was the most complex thing I had made at the time, I had few troubles completing it using my SX3 mill and 9x lathe. I did take it slow though... I was paranoid about ruining a casting, so I checked every set-up a dozen times before making cuts!

Andy also gives clear instructions on how to make the parallel machine files, from common hand files. Parallel machine files of the correct size and cut are not available in my area, and hard to find worldwide, so this is important.

Unfortunately I made this tool before I started making videos, so I don't have any construction pics for you, but please ask if you have any questions.