Wheel Crossing Jig

Wheel Crossing Jig based on the design by J Malcolm Wild

Wheel Crossing Jig based on the design by J Malcolm Wild

There are 2 books that I reach for on almost a daily basis. "Watchmaking" by George Daniels, and the other is "Wheel And Pinion Cutting In Horology" by Malcolm Wild. Both are quite simply "must have" books for a watch or clockmaker. They're jam packed with diagrams, explanations, tools, and overall best practice information.

The latter book is the source for the design of this tool. And what a timesaver this one is. It assists in one of the most time consuming tasks for a clockmaker, the crossing out of clock wheels.

Accurate marking out of the spoke lines is critical to getting a good result, and generally speaking this takes a fair amount of time if you do it manually. However this jig simplifies the task by taking care of the basic geometry. Once you get set up, its a breeze to do the marking out.

The latter book is the source for the design of this tool. And what a timesaver this one is. It assists in one of the most time consuming tasks for a clockmaker, the crossing out of clock wheels.

Accurate marking out of the spoke lines is critical to getting a good result, and generally speaking this takes a fair amount of time if you do it manually. However this jig simplifies the task by taking care of the basic geometry. Once you get set up, its a breeze to do the marking out.

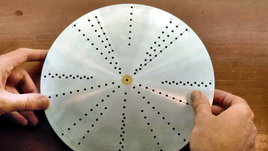

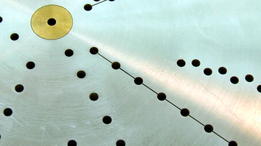

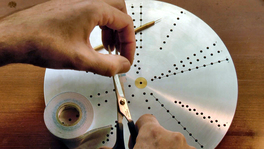

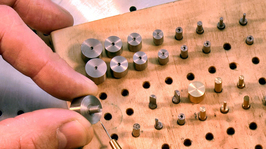

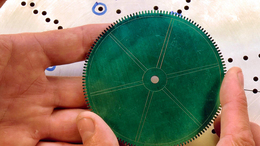

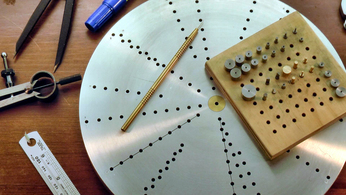

The tool consists of a base, drilled with an array of holes that are radially spaced to give basic indexing for spoke patters of 4, 5, 6 and 8 - the traditional wheel spoke pattern numbers. A set of shouldered pegs are turned to fit the holes, and they provide guidance for the ruler to set the appropriate width of the spoke at the hub, and at the perimeter. The peg diameters are turned as required to generate the required spoke taper. If you have a CAD program, calculating these peg diameters is a snack. If not, high school trig will still get you there, but with a sore head...

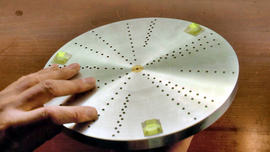

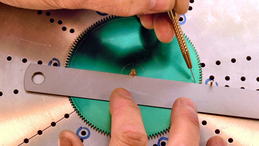

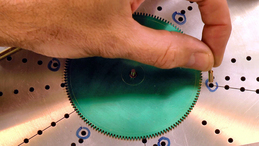

To mark out a wheel crossing, the wheel is first fixed to the base with double sided tape. Once it is in place, the perimeter circles are scribed with a divider.

The appropriate pegs are then inserted into the center and perimeter holes, and the ruler is held up against them. The line is then simply marked out with a scriber. How easy is that? I am now in the habit of marking out the appropriate holes with a sharpie, so I don't make any silly mistakes.

I made this tool before I started making videos, so I don't have any build pics to show you. But you can see it involved a LOT of hole drilling. There's more holes in that plate than it would perhaps seem! I modified JMW's design quite a bit to suit my needs. First by making it a lot larger, to accommodate quite large wheels. And secondly by making the hole pattern continuous to the edge of the plate. It just seems more versatile to me to do it that way. I also made mine out of aluminum alloy, and put a brass bushing in the center to resist wear.

This tool also doubles as a platform for the circular graining of wheels, dials and chapter rings. Also it serves for the basic index/marking out of any flat circular component that needs to have drill holes marked out. eg Dial bezel screw locations etc.

If you're considering making a clock in the home shop, I strongly recommend that you buy Malcolm Wild's book, and make this tool. You can also buy it directly from his website.

The appropriate pegs are then inserted into the center and perimeter holes, and the ruler is held up against them. The line is then simply marked out with a scriber. How easy is that? I am now in the habit of marking out the appropriate holes with a sharpie, so I don't make any silly mistakes.

I made this tool before I started making videos, so I don't have any build pics to show you. But you can see it involved a LOT of hole drilling. There's more holes in that plate than it would perhaps seem! I modified JMW's design quite a bit to suit my needs. First by making it a lot larger, to accommodate quite large wheels. And secondly by making the hole pattern continuous to the edge of the plate. It just seems more versatile to me to do it that way. I also made mine out of aluminum alloy, and put a brass bushing in the center to resist wear.

This tool also doubles as a platform for the circular graining of wheels, dials and chapter rings. Also it serves for the basic index/marking out of any flat circular component that needs to have drill holes marked out. eg Dial bezel screw locations etc.

If you're considering making a clock in the home shop, I strongly recommend that you buy Malcolm Wild's book, and make this tool. You can also buy it directly from his website.