Movement Clamps, Plate Holding Screws or "Old Timers" Clamps

"Old Timer" Clamps

"Old Timer" Clamps

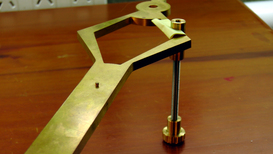

There are usually quite a few components that protrude beyond the clock plates, like pivots, arbor ends and so on, that can become pushed out of place, or damaged if the movement is simply placed flat upon the bench.

A simple solution is to just use an upturned shoe box as a platform, but this tool is a little more elegant.

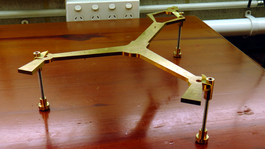

The clamps fit to the lower plate, and lift it well clear of the bench, so that during assembly, the pivots will seat in their pivot holes, and stay there. It also keeps other parts like the crutch, and perhaps calendar/striking/motion work, that may be fixed outside the plates, clear of contact with the bench, when the assembled movement is being handled.

Described in John Wilding's book "Tools for the Clockmaker And Repairer", this is the first tool that I made for the shop, and you may have noticed a picture of it as the welcome image on the Youtube channel and Facebook pages. It was an excellent first project, with both lathe and milling work. By the time I finished this one, I was hooked on making stuff in the home shop.

A simple solution is to just use an upturned shoe box as a platform, but this tool is a little more elegant.

The clamps fit to the lower plate, and lift it well clear of the bench, so that during assembly, the pivots will seat in their pivot holes, and stay there. It also keeps other parts like the crutch, and perhaps calendar/striking/motion work, that may be fixed outside the plates, clear of contact with the bench, when the assembled movement is being handled.

Described in John Wilding's book "Tools for the Clockmaker And Repairer", this is the first tool that I made for the shop, and you may have noticed a picture of it as the welcome image on the Youtube channel and Facebook pages. It was an excellent first project, with both lathe and milling work. By the time I finished this one, I was hooked on making stuff in the home shop.

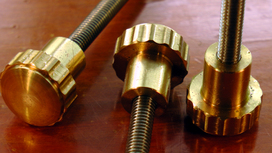

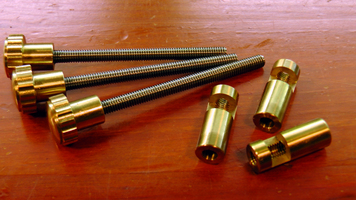

The heads were turned and threaded for the rod, then a section was milled out, just past half of the diameter. The feet were a real fun part. The rotary table was used on the mill, to put plunge cut grooves around the perimeter for the grip, and the domed parts were completed using a graver. The domed shape ensures that the 3 legs make a natural stable platform.

There are so many unique, and interesting tools like this, associated with clockmaking. They are all fun to make, essential to doing the job properly, and in many cases can no longer be purchased.

3 excellent reasons to make them in the home shop.

There are so many unique, and interesting tools like this, associated with clockmaking. They are all fun to make, essential to doing the job properly, and in many cases can no longer be purchased.

3 excellent reasons to make them in the home shop.